Heat treatment equipment

Furnaces and peripherals

We specialize in the production, modernization and servicing of heat treatment equipment. We have an internal design office in the mechanical and electrical field and a section for programming logic controllers. We have production preparation facilities, production and assembly plant for heat treatment equipment and service staff.

We combine specialist knowledge and unique experience gained in partnership with companies recognized in the heat treatment industry. We provide technically and technologically advanced equipment for heat and thermochemical treatment in reactive and protective atmospheres.

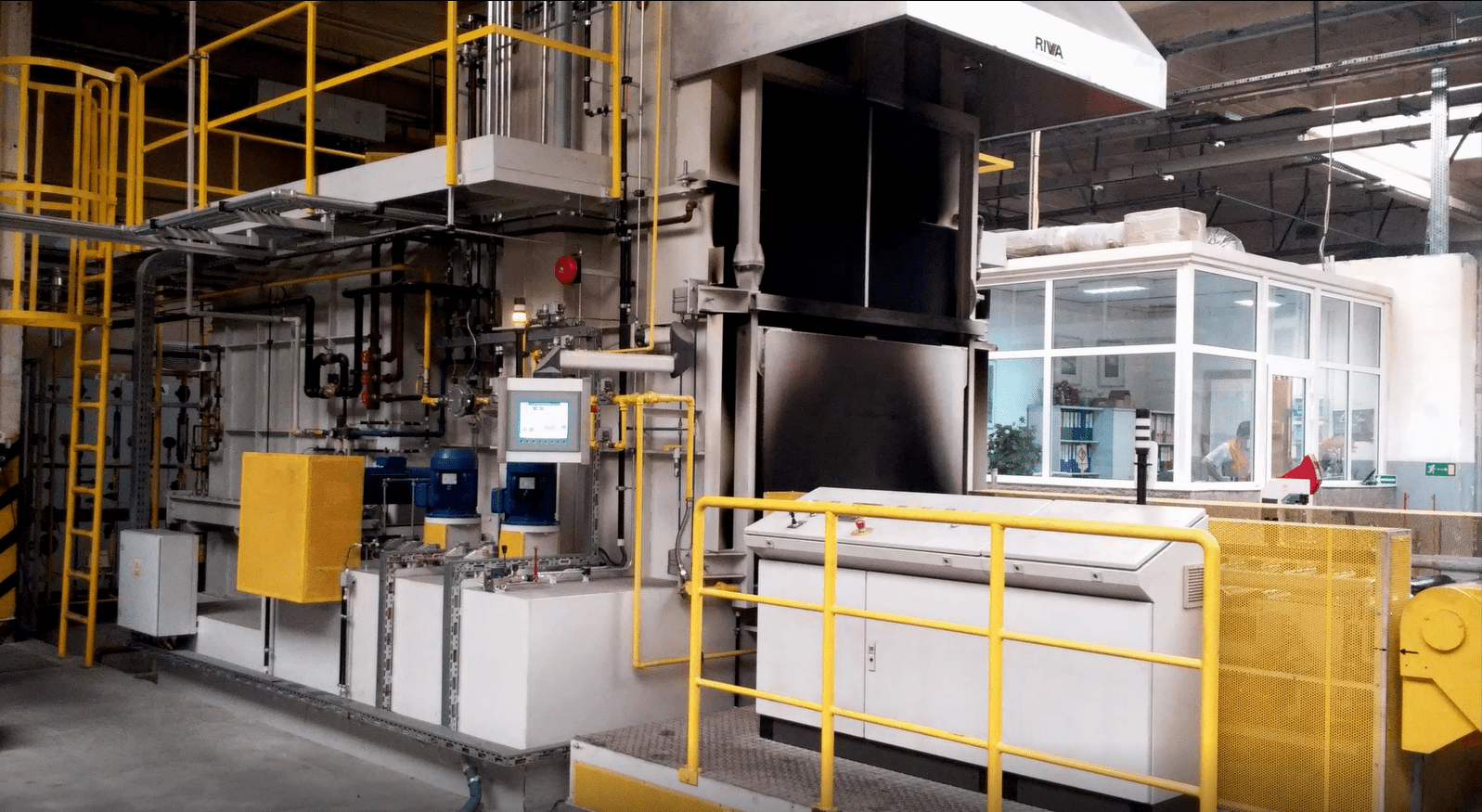

RMK multifunctional furnace – nominal temperature 1000°C

Modern equipment for heat treatment.

We offer furnaces and peripherals for a variety of metal heat treatment applications, including:

-

Multifunctional chamber furnaces for carburizing and hardening

With one or two heating and process chambers and an integrated vestibule with an oil quenching bath or a gas cooling chamber.

-

Sealed-quench furnaces for carburizing and low-deformation hardening of spatial details (individually or in stacks)

Do precyzyjnej obróbki termochemicznej i niskodeformacyjnego hartowania w wannach olejowych w aktywnym zacisku.

-

Rotary hearth furnace sockets with a self-designed hardening press for hardening in dies (manual or robotic handling)

-

Seats of furnaces with a rotary hearth or devices for induction heating in the inert atmosphere with a hardening press of our own design for hardening ring-type elements on calibrated mandrels (for manual or robotic operation)

Endothermic atmosphere generator

-

Cells of pit furnaces with hardening baths

-

Lines of belt furnaces for various applications, adapted to technological requirements

-

Sealed-quench furnaces

For a variety of high- and low-temperature processes, optionally with protective atmosphere and integrated sub-zero treatment.

-

Endothermic atmosphere generators

With a capacity of 21 m3 to 180 m3 and a high degree of automation, optionally with automatic capacity control.

-

Loaders for the line of sealed-quench furnaces for manual or automatic handling

-

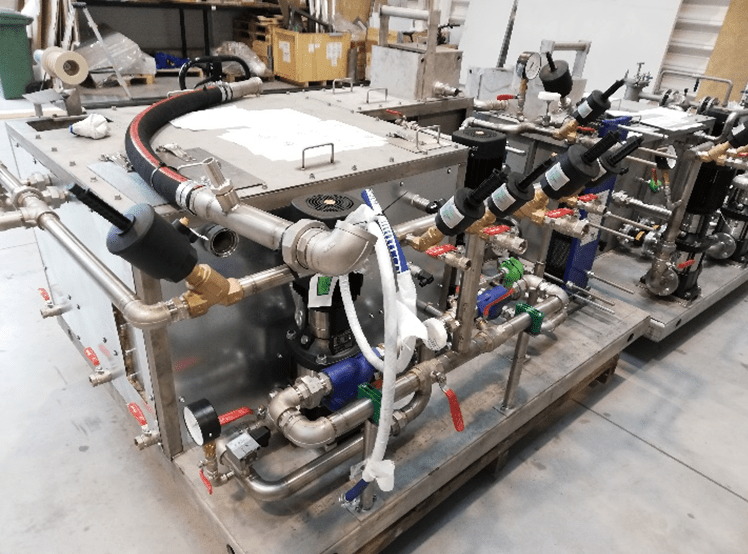

Cooling water systems in open and pressurized systems

-

Intelligent nitrogen supply systems for furnaces integrated with furnace control systems with prioritization of demand, optimization of gas consumption as well as leak control and warning systems.

Polymer cooling system

RRMK furnace for carburizing and hardening

We are your partner in the design, construction and delivery of equipment and entire production lines.