Polcasting Group

Solutions for the industry

The Polcasting Group is a group of engineering and production companies focused around the family enterprise established in 1994.

The main task of the company is the automatize the industrial processes. We integrate existing devices into manufacturing cells and production lines. Whenever the automation has to go further, we design fully-automated, multifunctional special machines for mass production which are replacing already existing manufacturing cells and production lines. Moreover, we implement individual projects combining various technologies of production, assembly, surface treatment and quality control of finished products.

All above mentioned actions are aimed at increasing the efficiency of machines and processes. We simplify inter-operational handling by offering automatic transfer and packing / palletizing systems for details as well as integrated robotic production, assembly and control stations. Once there are more than just one operation in production, we provide manipulators as well as specialized transport, loading-unloading and feeding devices. Therefore, we improve the comfort, safety and ergonomics of work in particularly difficult thermal conditions and exposure to emissions at the workplace and in the greater scale of entire production departments. Furthermore, we design and install superior control systems, supervision systems for manual and semi-automatic lines, protective gas installations, etc.

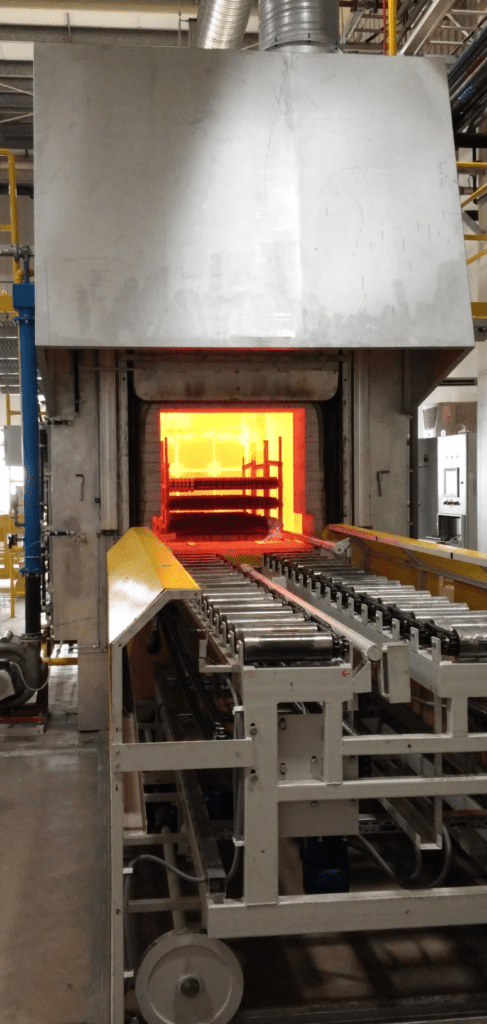

Complete production line

A separate activity of the Group is the production of devices for the heat treatment industry. We manufacture and supply devices for both bulk and surface heat treatment. We are capable of equipping heat treatment plants with the complete set of devices and systems: furnaces, washers, automatic loading devices, peripheral devices (endogenerators, closed cooling water systems), gas installations, security systems, superior control and quality control systems.

We undertake comprehensive repairs and modernization of heat treatment devices, special machines, machines with induction heating or hydraulic drives.

The Group develops its activities based on its own technical thought and many years of experience gained in the implementation of technically advanced projects on three continents.

History of the Polcasting Group

September 1994 r.

Foundation of Polcasting Sp. z o.o.

June 1995 r.

The first heat treatment device

Delivery of the first device for heat treatment, aluminum supersaturation, for the VW Hannover experimental foundry - in cooperation with ELTERMA S.A.

January 2002 r.

Foundation of the nitrocarburizing plant Hartownia TS Zbąszynek Sp. z o.o.

Establishing as a joint venture with the French partner HEF France - nitrocarburizing plant Hartownia TS Zbąszynek Sp. z o.o. This company has provided the Group with the very first practical experience of a user and service provider in the thermochemical treatment plant. Today, Hartownia TS Zbąszenk is one of the largest professional providers of nitrocarburizing services in the CLIN technology in Europe, a partner of the automotive, electrotechnical and machine industries, hydraulic manufacturers, etc. with unique experience in the field of thermochemical and surface treatment.

February 2004 r.

Foundation of RIVA Sp. z o.o.

Establishing as a joint venture with the German partner IVA-Dortmund - a specialized manufacturer of heat treatment equipment - RIVA Sp. z o.o. Along with acquiring technical competences, RIVA was invited as a member of different industrial groups - from 2006 Metal Technology Holding (De / Fr / Cn / PL), and then the Italian TENOVA group (2013). Since 2018, RIVA has been a company with 100% Polish capital.

July 2006 r.

Foundation of the second branch of Hartownia TS Zbąszynek Sp. z o.o.

Establishment of the next production plant of Hartownia TS Zbąszynek located in Siemianowice Śląskie. Since then, it has been equipped almost solely within the Polcasting group.

March 2015 r.

Construction of the first integrated heat treatment line.

Delivery of the first integrated line for quenching and tempering (rail fastening elements).

from 2015 r.

Design, delivery and commissioning of the first complete heat treatment plant

Delivery of the first complete heat treatment plant equipped with devices, infrastructure, instrumentation, superior control system and security systems (for a manufacturer of automotive components in Tianjin - China).

July 2017 r.

Construction of the first multi-functional machine (for hardening and tempering of precision elements for the automatic transmissions)

Production of the first fully-automatic multi-functional machines combining loading technologies through a vacuum lock, controlled atmosphere inside the device in a gas-tight housing, induction heating, precise hardening of toothed elements on a calibrated mandrel, polymer conditioning, automatic transfer of parts, on-line control with selection of OK and NOK products and washing.

May 2019 r.

Joining of Centrum Projekt Sp. z o. o. to the Polcasting Group

Joining to the Polcasting group an experienced supplier of solutions in the field of automation of production processes - Centrum Projekt Sp. z o.o. company. It resulted in the enrichment of design and production capabilities in the field of automation of technical processes.

Polcasting Group today

The Polcasting Group, together with a proven group of long-term partners supplementing internal competences and production capacities, provides technically and technologically advanced machines, devices and solutions in the field of process automation and in-house logistics. We provide a high level of competitiveness for various industries. Examples of advanced solutions are individually designed production stations and special machines working in the glass, automotive, metal, furniture and many other industries. Evidences of innovative technical solutions on an international scale are a system of non-deformation heat treatment of flat elements installed in a hardening furnace or a machine integrating the full production cycle of footwear wipers.

We are your partner in the supply and modernization of equipment and entire production lines.

Multi-chamber oven